PIMag® Linear stage, 80 mm width, 25 mm travel range, 80 N load capacity, incremental linear encoder with sin/cos signal transmission, 80 µm sensor signal period, iron core 3-phase linear motor, 48 V

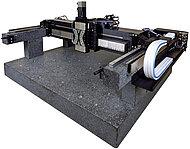

V-408 PIMag® Linear Stage

Inexpensive, with Linear Motor

- Crossed roller guide for high load capacity

- Minimum incremental motion 20 nm

- Bidirectional repeatability ±0.1 µm

- Compact design

- Low price

- Iron core PIMag® linear motor developed by PI

PIMag® linear motor

Linear motors are electromagnetic direct drives. They dispense with mechanical components in the drivetrain and transfer the drive force directly and friction-free to the motion platform. The drives reach high velocities and accelerations. Iron core motors are used when forces and accelerations need to be achieved in a limited installation space. The design with iron cores maximizes the magnetic forces and ensures high thermal stability of the drive.

PIMag®

PI develops proprietary magnetic motors if positioning systems need to achieve specific performance characteristics that cannot be reached by using drive components currently available on the market, for example, to achieve a high force density or a compact design. The motors developed by PI are identified by the PIMag® brand name.

Crossed roller guide

With crossed roller guides, the point contact of the balls in ball guides is replaced by line contact of the hardened rollers. Consequently, they are considerably stiffer and need less preload, which reduces friction and allows smoother running. Crossed roller guides are also distinguished by high guiding accuracy and load capacity. Force-guided rolling element cages prevent cage creep.

Direct position measuring

Position measuring is performed with the highest accuracy directly at the motion platform so that nonlinearity, mechanical play, or elastic deformation have no influence on position measuring.

Application fields

Industry and research. Automation technology with high demands on dynamics and precision.

Specifications

Specifications

| Motion | V-408.132020 | V-408.232020 | Tolerance |

|---|---|---|---|

| Active axes | X | X | |

| Travel range in X | 25 mm | 50 mm | |

| Maximum velocity in X, unloaded | 500 mm/s | 700 mm/s | |

| Straightness error in Y (straightness) | ± 4 µm | ± 4 µm | typ. |

| Straightness error in Z (flatness) | ± 4 µm | ± 4 µm | typ. |

| Angular error around Y (pitch) | ± 150 µrad | ± 150 µrad | typ. |

| Angular error around Z (yaw) | ± 150 µrad | ± 150 µrad | typ. |

| Positioning | V-408.132020 | V-408.232020 | Tolerance |

| Minimum incremental motion in X | 0.02 µm | 0.02 µm | typ. |

| Bidirectional repeatability in X | 0.2 µm | 0.2 µm | typ. |

| Reference switch | Optical, direction sensing (pulse signal), 5 V, TTL | Optical, direction sensing (pulse signal), 5 V, TTL | |

| Limit switches | Hall effect, N/O contact, 5 V, TTL | Hall effect, N/O contact, 5 V, TTL | |

| Integrated sensor | Incremental linear encoder | Incremental linear encoder | |

| Sensor signal | Sin/cos, 1 V peak-peak | Sin/cos, 1 V peak-peak | |

| Sensor signal period | 80 µm | 80 µm | |

| Sensor resolution | 10 nm | 10 nm | |

| Drive Properties | V-408.132020 | V-408.232020 | Tolerance |

| Drive type | Iron core 3-phase linear motor | Iron core 3-phase linear motor | |

| Nominal voltage | 24 V | 24 V | |

| Nominal current, RMS | 1.1 A | 1.1 A | typ. |

| Peak current, RMS | 3.2 A | 3.2 A | typ. |

| Drive force in X | 5 N | 5 N | typ. |

| Peak force in X | 14 N | 14 N | |

| Force constant | 4.6 N/A | 4.6 N/A | |

| Resistance phase-phase | 2.46 Ω | 2.46 Ω | typ. |

| Inductance phase-phase | 1.94 mH | 1.94 mH | |

| Back EMF | 2.81 V·s/m | 2.81 V·s/m | max. |

| Pole pitch N-N | 18 mm | 18 mm | |

| Permissible maximum temperature for drive components | 80 °C | 80 °C | |

| Mechanical Properties | V-408.132020 | V-408.232020 | Tolerance |

| Permissible push force in Y | 80 N | 80 N | max. |

| Permissible push force in Z | 80 N | 80 N | max. |

| Permissible torque in θX | 2.3 N·m | 2.3 N·m | max. |

| Permissible torque in θY | 1.3 N·m | 1.3 N·m | max. |

| Permissible torque in θZ | 1.3 N·m | 1.3 N·m | max. |

| Moved mass in X, unloaded | 230 g | 300 g | |

| Guide | Crossed roller guide | Crossed roller guide | |

| Overall mass | 790 g | 940 g | |

| Mass without cable | 500 g | 650 g | |

| Material | Aluminum, black anodized | Aluminum, black anodized | |

| Miscellaneous | V-408.132020 | V-408.232020 | Tolerance |

| Operating temperature range | 5 to 40 °C | 5 to 40 °C | |

| Connector | HD D-sub 26 (m) | HD D-sub 26 (m) | |

| Sensor connector | D-sub 15 (f) | D-sub 15 (f) | |

| Cable length | 2 m | 2 m | |

| Recommended controllers/drivers | C-891, C-885 with C-891.10C885 A-811.CE G-901 | C-891, C-885 with C-891.10C885 A-811.CE G-901 |

Note on sensor resolution: interpolated

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Datasheet

Documentation

User Manual V408M0001

V-408.132020 PIMAG® POSITIONERS

User Manual V408M0002

V-408.232020 PIMAG® POSITIONERS

3D Models

V-408 3D model

Animated 3-D Models

Animated 3-D Model V-408.232020

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

PIMag® Linear stage, 80 mm width, 50 mm travel range, 80 N load capacity, incremental linear encoder with sin/cos signal transmission, 80 µm sensor signal period, iron core 3-phase linear motor, 48 V