Piezoceramic Plates, Blocks, and Rods

A Wide Range of Materials and Geometries for Application-Specific Precision

- High quality components

- Tight mechanical tolerances

- High geometric flexibility (1 mm to 80 mm)

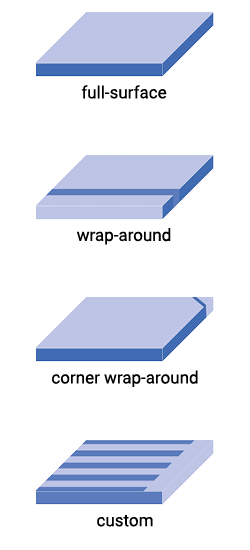

- Screen printed and sputtered electrodes available, including wrap-around contacts and structured electrodes

- Optional: Manufacturing of industrial-grade assemblies, including electrical connections using wires or flexible circuit boards

Piezoelectric plates can be used in a wide range of fields, from ultrasonic technology to sensor and actuator applications. Choosing the right piezoceramic material always depends on the specific requirements of the application. The plates are manufactured in various sizes and designs to ensure seamless integration with customized systems.

In the industrial sector, piezo components are used in applications such as pressure sensors, sonar technology, and nondestructive material testing. In medical systems, they support high-resolution diagnostic imaging techniques.

A coordinated and combined approach to assembly and connection technology enables the creation of customized piezo components.

Specifications

With over 30 years of expertise in the development and manufacturing of piezoceramics, PI Ceramic offers a comprehensive range of services - from targeted material selection to the development of customized, application-based solutions.

The dimensions of the piezo plates are individually adjusted within defined specification limits. Feasibility is thoroughly assessed based on the submitted requirements and measurements.

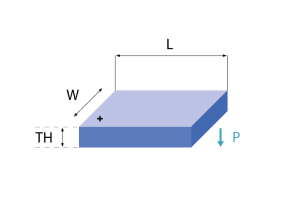

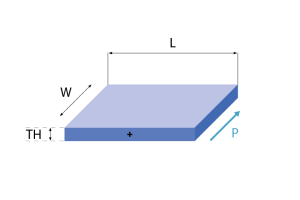

| Length L [mm] | 1 to 80 <75 for shear plates |

| Width W [mm] | 1 to 60 |

| Thickness TH [mm] | 0.1 to 30 0.2 to 10 for shear plates |

| Electrodes | Thick layer (Ag), thin layer (Ag, Au, CuNi, Cu, NiV), electroless nickel |

| Electrode designs | Choose from various designs: full-surface, edge wrap-around, corner wrap-around, custom (see right column) |

| Termination | Various electrical connection methods are available, such as soldering or bonding wires and flexible circuit boards. |

| Polarization direction | Depending on the design of the piezo components, different displacements are possible in axial, radial, and shear directions. For further information see >> Operating Modes. |

| Material | We offer various ferroelectric soft and hard PTZ materials as well as lead-free alternatives. A material overview can be found >> here. The corresponding datasheets can be found >> here. |

| Added capabilitites | In addition to a higher degree of enhancement through assembly and connection technology, customized, installation-ready piezo components can be created, such as:

|

| Applications | Piezoceramic plates are suitable for a wide range of sensor and actuator applications. Examples of possible applications can be found >> here. |

Operating Modes

Piezoceramic plates can be used as sensors and actuators. In sensor mode, the plates convert mechanical loads - such as pressure or ultrasound - into electrical signals via the direct piezoelectric effect.

If the piezo plate is used as an actuator, applying an electrical voltage results in mechanical displacement.

When using DC voltage, this can take the form of static deformation, or, when powered by AC voltage, as oscillations, for example, in the ultrasound range. The direction of motion - either axial or radial - depends on the design of the piezo component. The displacement amplitude is determined by both the dimensions of the piezo plate and the applied voltage.

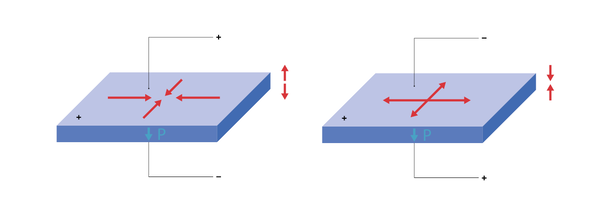

For plates with positive polarization direction at the top and negative polarization at the bottom, the following displacement directions apply:

An axial displacement (d33-effect) always causes a slight deformation in the radial direction (d31-effect) as well.

To reach certain resonant frequencies in the axial vibration mode, it is necessary to change the plate thickness. For frequencies in the radial direction, their diameters have to be adjusted. The following applies for both variants: The larger the dimension, the lower the frequency.

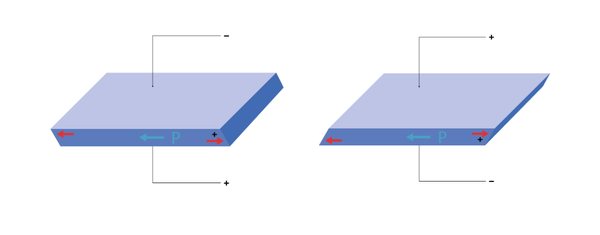

The following displacements apply for shear plates:

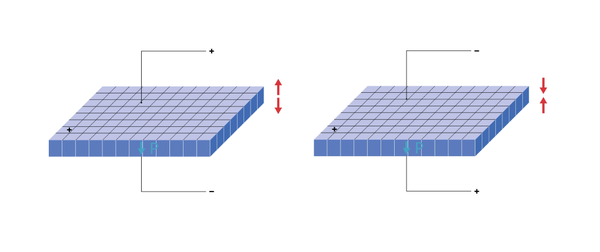

Piezo plates can be produced as 1-3 composites to achieve a higher axial displacement while minimizing radial deformation.

The combination of piezoceramics and polymer enables high electromechanical coupling and a high bandwidth in the axial direction.

- Ultrasonic cleaning

- Ultrasonic welding

- Precision positioning

- Pressure sensors

- Non-destructive testing

- Tactile feedback

- Energy harvesting

- Hydro acoustics

Downloads

Material Data

Lead-Free Piezoceramic Materials

User Manual A000T0047

Handling and Electrical Contacting of Piezo Components