High-precision hexapod; minimum incremental motion X,Y 40 nm, minimum incremental motion Z 20 nm, minimum incremental motion θX, θY 0.2 µrad, minimum incremental motion θZ, 0.4 µrad, measurement report included in the scope of delivery; brushless DC gear motor; incremental rotary encoder; 30 kg payload; 2.5 mm/s maximum velocity. Connecting cables are not in the scope of delivery and must be ordered separately.

H-840.G2IHP Hexapod

Inexpensive and High Precision

- Minimum incremental motion 0.04 µm / 0.04 µm / 0.02 µm

- Travel range ±50 mm / ±50 mm / ±25 mm

- Rotation range ±15° / ±15° / ±30°

- Repeatability to ±0.1 µm

- Payload 30 kg

Steps of 40 nm in X, Y, and 20 nm in Z ensure that the H-840.G2IHP meets the highest demands of alignment and positioning applications in production and measuring technology. As with the entire H-840 hexapod series, the design and layout is robust and provides long travel ranges for more task flexibility. A measurement report on the step size is included in each single shipment.

Further models, e.g., with absolute encoder or for high dynamics, are listed in the datasheet for the H-840.

The parallel-kinematic design for 6 degrees of freedom makes it significantly more compact and stiffer than comparable serial kinematic systems. The advantages over serial, i.e., stacked systems, are mainly the much better path accuracy and repeatability. In addition, the moved mass is lower and allows improved dynamics which is the same for all motion axes. Cable management is not a problem because cables are not moved.

Use of BLDC motors

Brushless DC motors are particularly suitable for high rotational speeds. They can be controlled very accurately and ensure high precision. Because they dispense with sliding contacts, they run smoothly, are wear-free and therefore achieve a long lifetime.

PIVirtualMove

The simulation software simulates the limits of the workspace and payload of a hexapod. Therefore, even before purchasing, you can check whether a particular hexapod model can handle the loads, forces, and torques occurring in an application. For this purpose, the simulation tool takes the position and motion of the hexapod as well as the pivot point and several reference coordinate systems into account.

Application fields

Industry and research. For tool inspection, life science, micromanufacturing, micromanipulation, industrial alignment systems. For assembly, alignment, and inspection of optical components.

Specifications

Specifications

| Motion | H-840.G2IHP | Tolerance |

|---|---|---|

| Active axes | X ǀ Y ǀ Z ǀ θX ǀ θY ǀ θZ | |

| Travel range in X | ± 50 mm | |

| Travel range in Y | ± 50 mm | |

| Travel range in Z | ± 25 mm | |

| Rotation range in θX | ± 15 ° | |

| Rotation range in θY | ± 15 ° | |

| Rotation range in θZ | ± 30 ° | |

| Maximum velocity in X | 2.5 mm/s | |

| Recommended velocity in X | 2 mm/s | |

| Maximum velocity in Y | 2.5 mm/s | |

| Recommended velocity in Y | 2 mm/s | |

| Maximum velocity in Z | 2.5 mm/s | |

| Recommended velocity in Z | 2 mm/s | |

| Maximum angular velocity in θX | 30 mrad/s | |

| Recommended angular velocity in θX | 25 mrad/s | |

| Maximum angular velocity in θY | 30 mrad/s | |

| Recommended angular velocity in θY | 25 mrad/s | |

| Maximum angular velocity in θZ | 30 mrad/s | |

| Recommended angular velocity in θZ | 25 mrad/s | |

| Positioning | H-840.G2IHP | Tolerance |

| Minimum incremental motion in X | 0.04 µm | typ. |

| Minimum incremental motion in Y | 0.04 µm | typ. |

| Minimum incremental motion in Z | 0.02 µm | typ. |

| Minimum incremental motion in θX | 0.2 µrad | typ. |

| Minimum incremental motion in θY | 0.2 µrad | typ. |

| Minimum incremental motion in θZ | 0.4 µrad | typ. |

| Unidirectional repeatability in X | ± 0.3 µm | typ. |

| Unidirectional repeatability in Y | ± 0.3 µm | typ. |

| Unidirectional repeatability in Z | ± 0.1 µm | typ. |

| Unidirectional repeatability in θX | ± 2.5 µrad | typ. |

| Unidirectional repeatability in θY | ± 2.5 µrad | typ. |

| Unidirectional repeatability in θZ | ± 3 µrad | typ. |

| Backlash in X | 2 µm | typ. |

| Backlash in Y | 2 µm | typ. |

| Backlash in Z | 0.3 µm | typ. |

| Backlash in θX | 5 µrad | typ. |

| Backlash in θY | 5 µrad | typ. |

| Backlash in θZ | 10 µrad | typ. |

| Integrated sensor | Incremental rotary encoder | |

| Drive Properties | H-840.G2IHP | Tolerance |

| Drive type | Brushless DC gear motor | |

| Nominal voltage | 24 V | |

| Mechanical Properties | H-840.G2IHP | Tolerance |

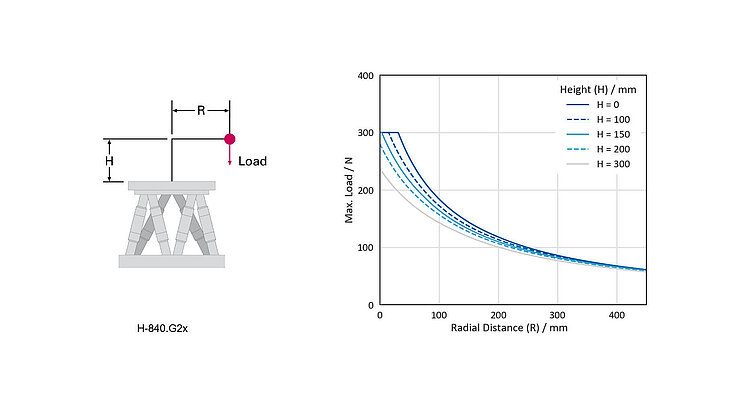

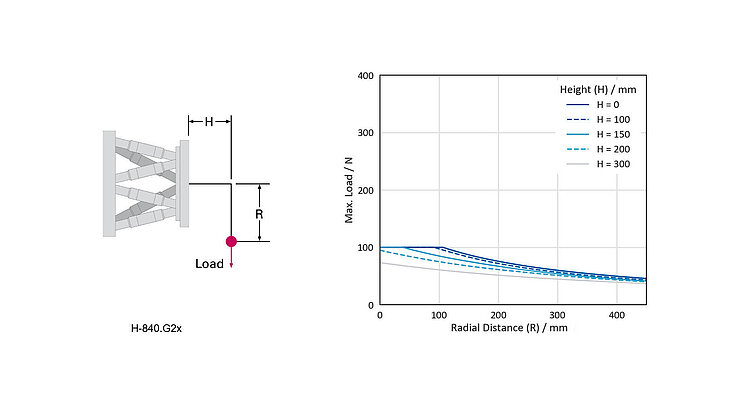

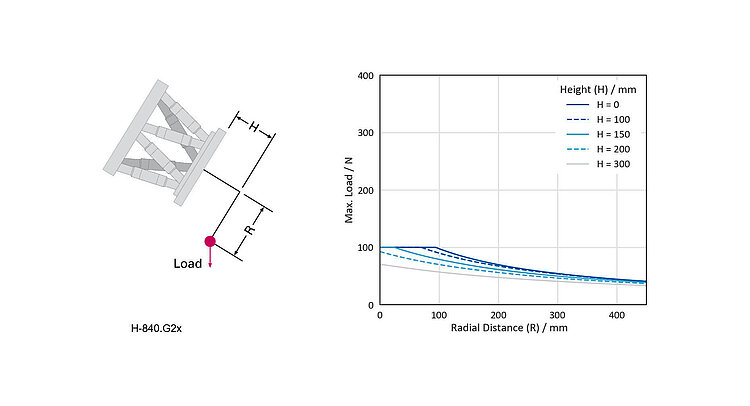

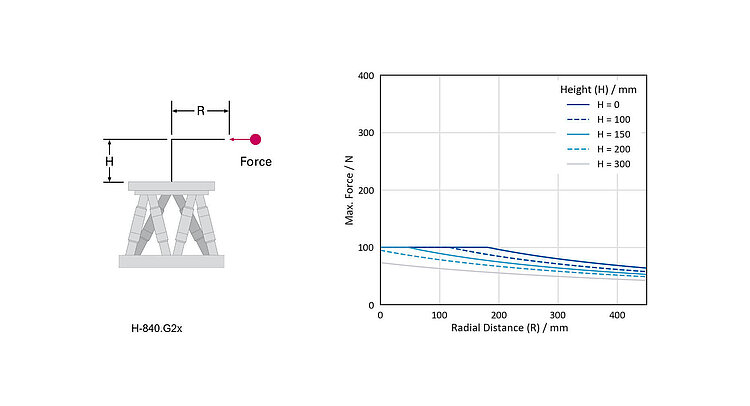

| Maximum load capacity, base plate in any orientation | 10 kg | |

| Maximum load capacity, base plate horizontal | 30 kg | |

| Maximum holding force, base plate in any orientation | 25 N | |

| Maximum holding force, base plate horizontal | 100 N | |

| Overall mass | 12 kg | |

| Material | Aluminum/steel | |

| Miscellaneous | H-840.G2IHP | Tolerance |

| Operating temperature range | -10 to 50 °C | |

| Connector for data transmission | HD D-sub 78 (m) | |

| Connector for supply voltage | M12 4-pole (m) | |

| Recommended controllers/drivers | C-887.5xx |

Connecting cables are not included in the scope of delivery and must be ordered separately.

Ask about customized versions.

When measuring position specifications, typical velocity is used. The data is included in the delivery of the product in the form of a measurement report and is stored at PI.

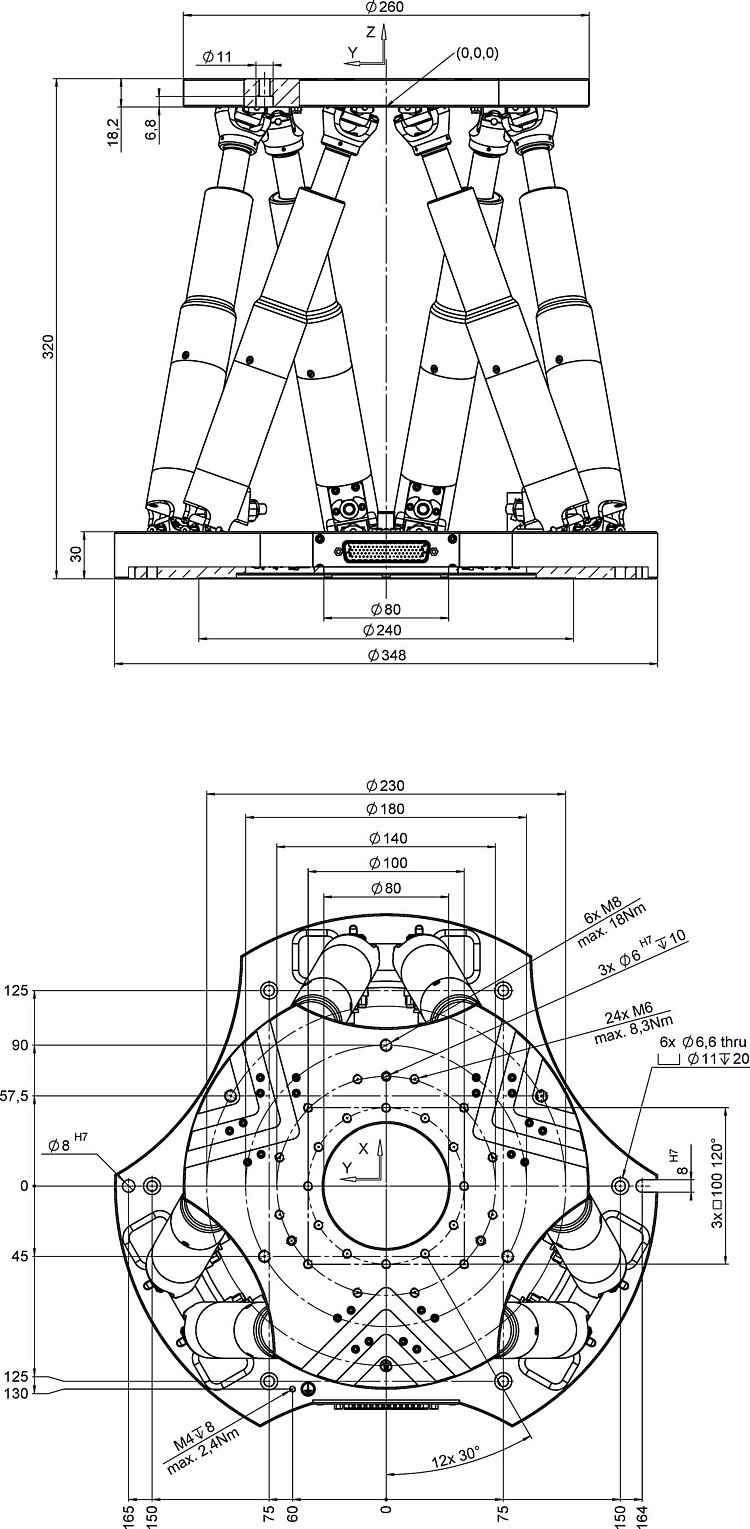

The maximum travel ranges of the individual coordinates (X, Y, Z, θX, θY, θZ) are interdependent. The data for each axis shows its maximum travel range when all other axes are in the zero position of the nominal travel range and the default coordinate system is in use, or rather when the pivot point is set to 0,0,0.

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Product Note

Product Change Notification Motor Driven Products

Datasheet

Documentation

PI Certificate of Registration of Vibratory Apparatus H-840

Certificate of Registration of Vibratory Apparatus

User Manual MS201

H-840 Hexapod Microrobot

3D Models

H-840.X2X 3D Model

Software Files

PIVirtualMove

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

How to Get a Quote

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Applications

Hexapods in Microproduction

What do optical components and glass fibers in photonics, mobile devices, and high-quality wristwatches all have in common?

Dimensional Measuring

Hexapods allow for an outstanding flexibility for a variety of samples of in-line automation systems by minimizing the space for motion robotics.