P-736 PInano® Z Microscope Scanner

Inexpensive, with Low Profile

- Step-and-settle to 5 ms

- Low overall height of 20 mm for easy integration

- Travel range 100 µm or 200 µm

- Clear aperture 93 mm × 65 mm

- E-709 digital piezo servo controller in the scope of delivery

- USB, RS-232, analog interfaces

Application fields

- Super-resolution microscopy

- Light disc microscopy

- Confocal microscopy

- 3-D imaging

- Screening

- Interferometry

- Measuring technology

- Autofocus systems

- Biotechnology

- Semiconductor tests

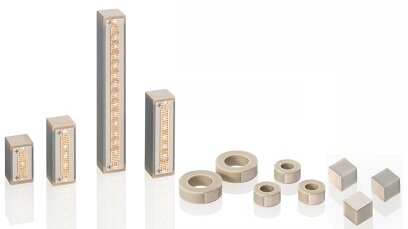

Outstanding lifetime thanks to PICMA® piezo actuators

The PICMA® piezo actuators are all-ceramic insulated. This protects them against humidity and failure resulting from an increase in leakage current. PICMA® actuators offer an up to ten times longer lifetime than conventional polymer-insulated actuators. 100 billion cycles without a single failure are proven.

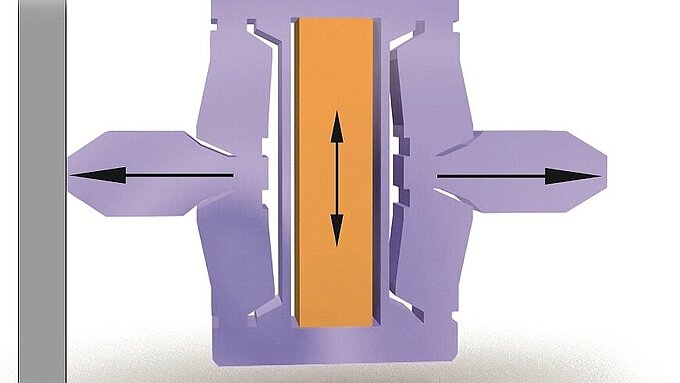

High guiding accuracy due to zero-play flexure guides

Flexure guides are free of maintenance, friction, and wear, and do not require lubrication. Their stiffness allows high load capacity and they are insensitive to shock and vibration. They work in a wide temperature range.

Automatic configuration and fast component exchange

Mechanics and controllers can be combined as required and exchanged quickly. All servo and linearization parameters are stored in the ID chip of the D-sub connector of the mechanics. The autocalibration function of the digital controllers uses this data each time the controller is switched on.

Extensive software for rapid start of productive operation

Thanks to support of MATLAB and NI LabVIEW as well as all common operating systems (Windows, Linux, and macOS), integration succeeds in virtually every environment – quickly and efficiently. Sophisticated programming examples and software tools such as PIMikroMove shorten the time to productive operation considerably.

Specifications

Specifications

P-736.ZR1S | P-736.ZR2S | Unit | Tolerance | |

|---|---|---|---|---|

Active axes | Z | Z | ||

Motion and positioning | ||||

Integrated sensor | Piezoresistive | Piezoresistive | ||

Travel range, closed loop | 100 | 200 | µm | |

Resolution, open loop | 0.2 | 0.4 | nm | typ. |

Resolution, closed loop | 0.4 | 0.7 | nm | typ. |

Mechanical properties | ||||

Settling time (10 % step width) | 5 | 7 | ms | |

Load capacity | 500 | 500 | g | max. |

Drive properties | ||||

Piezo ceramic | PICMA® P-885 | PICMA® P-885 | ||

Miscellaneous | ||||

Operating temperature range | 15 to 40 | 15 to 40 | °C | |

Material | Aluminum | Aluminum | ||

Mass | 550 | 550 | g | ±5 % |

Cable length | 1.5 | 1.5 | m | ±10 mm |

Piezo controller | E-709 digital servo (in the scope of delivery) | |||

Communication interfaces | USB, RS-232, SPI | |||

I/O connector | HD D-sub 26 1× analog input 0 to 10 V 1× sensor monitor 0 to10 V 1× digital input (LVTTL, programmable) 1× analog output 5× digital outputs (LVTTL, 3× predefined, 2× programmable) | |||

Command set | PI General Command Set (GCS) | |||

User software | PIMikroMove | |||

Software drivers | NI LabVIEW driver, dynamic libraries for Windows and Linux | |||

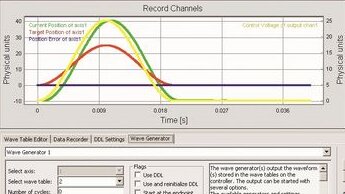

Supported functions | Wave generator, data recorder, autozero, trigger I/O, MATLAB, µManager | |||

Controller dimensions | 160 mm × 96 mm × 33 mm | |||

Downloads

Product Note

Product Change Notification Piezo Actuator Driven Products

Datasheet

Documentation

User Manual P736T0002

P-736.ZRxS PInano® piezo scanner (part of the P-736.ZRxS piezo scanner systems)

User Manual PZ222

E-709 Digital Piezo Controller, 1 Channel, -30 to 130 V

3D Models

3-D model P-736.ZR2

3-D model P-736.ZR1

Brochure

Microscope Stage Configurator

Sample Stages and Holders for Inverted Microscopes

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technology

PICMA® Technology

Highly reliable and extended lifetime through the patented manufacturing process for multilayer actuators.

Flexure Guiding Systems

Flexure guides from PI have proven their worth in nanopositioning. They guide the piezo actuator and ensure a straight motion without tilting or lateral offset.

Digital Motion Controllers

Digital technology opens up possibilities for improving performance in control engineering which do not exist with conventional analog technology.