Measuring Technology in Detail for Standard Products

Qualification as well as final and approval tests take place in the respective production fractal. PI qualifies its products with measuring equipment that is calibrated and can be traced back to a normal.

- PI uses high-resolution interferometers from leading manufacturers for precision path and length measuring that are accurate to within a few nanometers.

- Depending on the angular range, angle measurements are made with autocollimators, inclinometers, incremental rotary encoders or interferometers.

- The lifetime and load tests are designed individually for a specific product line and performed in the appropriate environment.

- Precision measuring is done on honeycomb tables that are isolated from vibration. The measuring environment and setup are adapted to the requirements of the respective product line.

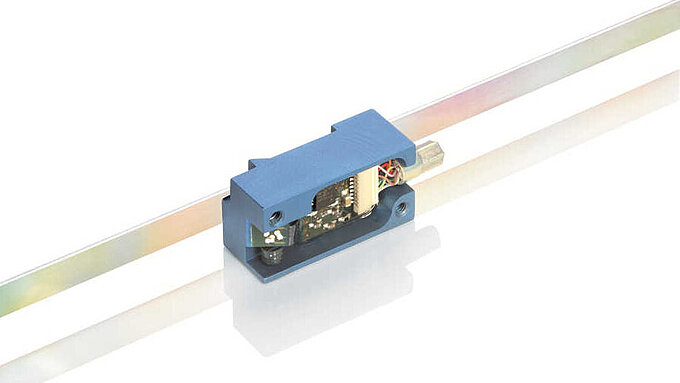

PI produces its own measuring technology with the PIOne incremental encoder and capacitive sensors. This sensor technology is intended primarily for installation into PI products but is also used in measuring equipment for production and qualification devices.

Nanometrology Laboratories

Nano measurement technology makes high demands on the stability and accuracy.

- Long-term measuring, where the position stability must be verified over several hours, and measuring less than a nanometer, are performed in special rooms with a stable climate.

- The seismic, electromagnetic, and thermal isolation of the test laboratories ensure a temperature stability of better than 0.25 °C over 24 hours. This makes accurate measuring possible down to the picometer range and sets the standard in measuring for nanopositioning products.

Measuring According to Customer Requirements

- Position accuracy is normally recorded on the motion platform. It can also be tested at any point defined by the application, e.g., for protruding loads. The test equipment is adapted for this purpose.

- Lifting and tilting equipment with a load capacity of 5 tons allows qualifying of positioning systems at any angle with application-specific alignment and load.

Learn more

- Various different trigger options allow synchronous data recording, e.g., simultaneous use of several interferometers

- Various measuring locations are available for qualifying under special ambient conditions:

- Cryochambers for measuring to 77°K (liquid nitrogen)

- Drying chambers (glovebox ..)

- Vacuums to 10-11 hPa

Learn more

Special Measuring Equipment

- A measuring location according to the capacitive measuring principle is available for measuring wobble and eccentricity.

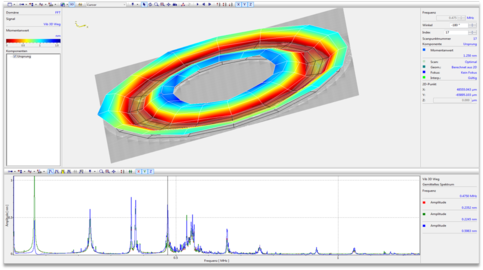

- PI has several white light interferometers for measuring the surface topology in material research.

- 3D coordinate measuring machines and a 6D laser tracker can be used for qualifying multi-axis systems, e.g., hexapods.

- High dynamics scanning vibrometers measure the motion characteristics of piezo elements during operation. This serves to check the displacement models and verify the desired excitation states.

- Vibrometers measure the velocity and vibration properties of positioning systems to max. 25 kHz.

Measurement Reports and Logs

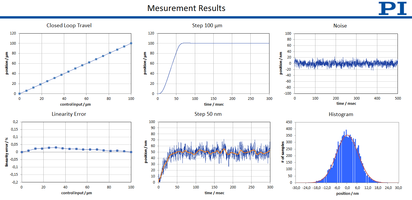

For PI, each individual measurement and qualification is an instrument for quality assurance. This makes sure that only those positioning systems leave the premises that are within the guaranteed specifications. All measurements are made with external, verifiable measuring equipment such as high-resolution interferometers.

The qualification data is verifiable for each individual product. The measurement data is compiled in a database and used for process control. Retraceability at product level is particularly interesting for large production runs.

The measurement log is provided with many systems such as hexapods or piezo systems. It is therefore possible for the customer to verify the performance of the system with the data measured before it was dispatched and also see which system components belong together.

Standards und Norms in Measuring Technology

Qualification of PI products is based on:

- DIN ISO 230-2

Test code for machine tools Part 2: Determination of accuracy and repeatability of positioning numerically controlled axes

- VDI/DGQ 3441

Statistical testing of the operational and positional accuracy of machine tools

Download

Manufacturing in Cleanrooms at PI (Physik Instrumente)

Capabilities and Capacity

This is how PI Does Measuring - Part I

Measuring Environment / Measuring Equipment Portfolio / Data Evaluation

This Is How PI Does Measuring - Part II

Positioning Accuracy, Repeatability, and similar Measurements: Measurement Procedure and Data Preparation at PI

This Is How PI Does Measuring - Part III

Resolution / Noise / Minimum Incremental Motion